The Ultimate Guide to Sandblasting Services in Oman

- Syed Arshad

- Oct 4, 2025

- 5 min read

Sandblasting, often referred to as grit blasting, is an essential process across several industries like

construction, manufacturing, and maintenance. As Oman's infrastructure and industrial sectors expand, the demand for sandblasting services has increased significantly. This guide offers a thorough overview of sandblasting services in Oman, focusing on different materials, benefits, and tips for selecting the right service provider.

What Is Sandblasting?

Sandblasting is a method that involves shooting abrasive materials at high speeds to clean, smooth, or engrave surfaces. This technique is frequently used to prepare surfaces for painting, remove rust, and enhance the appearance of various materials.

Given Oman's challenging environmental conditions, sandblasting services are vital for preserving the integrity of structures and equipment. Companies can choose from various abrasives like garnet, copperslag, and aluminum oxide, depending on the specific demands of their projects.

Types of Abrasives Used in Sandblasting

Garnet

Garnet is a popular choice for sandblasting due to its effectiveness and eco-friendliness. This natural mineral has a sharp cutting edge, making it suitable for various applications such as surface preparation and paint removal.

Using garnet can result in a cleaner end product, free of contaminants, which is especially important in industries like aerospace where precision is necessary. Approximately 20% of companies in Oman now prefer garnet due to its lower environmental impact compared to alternatives.

Copperslag

Copperslag, a byproduct of copper production, stands out for its cost-effectiveness and efficiency. It excels in heavy-duty applications, easily removing thick coatings and rust from metal surfaces.

Businesses that have shifted to using copperslag have reported a reduction in preparation time by nearly 30%. This efficiency allows companies to manage larger projects and meet tighter deadlines without sacrificing quality.

Aluminum Oxide

Aluminum oxide is another common abrasive in the sandblasting industry. Known for its durability, it helps produce very smooth finishes on various surfaces.

This abrasive is particularly effective for precise applications like etching glass or preparing surfaces for painting. Its versatility contributes to its popularity among sandblasting companies in Oman, with about 15% of companies highlighting it as their go-to abrasive.

Advantages of Sandblasting

Surface Preparation

Sandblasting is an excellent method for getting surfaces ready for painting or coating. By eliminating contaminants, rust, and older paint, sandblasting ensures that new coatings adhere effectively. This leads to a finish that can last up to 50% longer.

Restoration

Sandblasting is highly effective for reviving the appearance of materials like metal, wood, and concrete. It can remove years of wear and tear, allowing surfaces to regain their original look. For instance, businesses restoring vehicles often see a remarkable 60% improvement in appearance.

Speed and Efficiency

Sandblasting is a rapid process that can save both time and labor costs. With advanced equipment, tasks that might take days with traditional methods can be completed in just hours. This efficiency not only accelerates project timelines but also minimizes overall costs.

Selecting a Sandblasting Company in Oman

Choosing the right sandblasting service provider in Oman involves several key considerations to guarantee quality and reliable results.

Experience and Expertise

Opt for a company with a solid reputation and extensive experience in the sandblasting field. Professionals with a demonstrated history can effectively navigate various project challenges, ensuring quality work every time.

Equipment and Technology

The equipment used in sandblasting significantly affects the outcome. Companies should utilize modern, well-maintained machines and high-quality abrasives to ensure the best results for your projects.

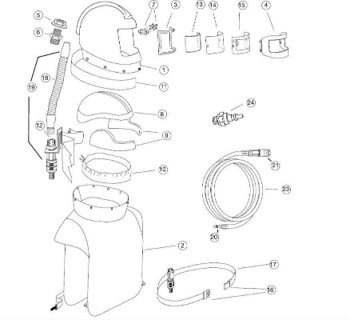

Ersaa Blast® brings you advanced sandblasting machines designed to deliver superior performance with reduced operating costs. Built with precision and reliability, our equipment ensures faster blasting cycles, consistent results, and longer service life. By combining modern engineering with high-quality materials, Ersaa Blast® helps you maximize productivity while maintaining cost efficiency – the perfect balance of power and value.

Ersaa Blast® – Engineered for performance, trusted for results.

Commitment to Safety

Safety should always be a primary concern in sandblasting. Select a company that follows strict safety standards to protect both workers and the surrounding environment. This commitment not only safeguards employees but also enhances the overall quality of work.

Customer Feedback

Researching customer reviews and testimonials can be enlightening. Positive feedback and case studies can offer insight into the quality of service, helping you make an informed choice.

Why Choose Ersaa Blast® in Oman?

At Ersaa Blast®, we don’t just sell equipment — we deliver complete blasting and painting solutions designed for Oman’s industries. From Muscat to Sohar, Duqm to Nizwa, Salalah to Sur, we support contractors, manufacturers, and maintenance providers with high-quality sandblasting machines, blasting accessories, airless painting machines, electrical painting machines, paint sprayers, and industrial coating equipment.

What Sets Us Apart?

✔ High-performance sandblasting machines – faster, safer, and cost-efficient

✔ Complete range of blasting accessories & spare parts – to keep your operations running smoothly

✔ Airless & electrical painting machines, industrial paint sprayers & coating systems – for precise, durable finishes

✔ End-to-end sandblasting & painting services across Oman – trusted by leading industries

✔ Proven track record – serving oil & gas, construction, marine, and manufacturing sectors

With Oman’s rapid growth in infrastructure and industrial development, the demand for modern blasting and painting solutions is at an all-time high. That’s why companies choose Ersaa Blast® — for equipment supply, accessories, and on-site blasting & coating services.

👉 If you are looking for sandblasting services in Oman or want to purchase blasting machines, airless painting machines, electrical painting machines, paint sprayers, or blasting accessories, Ersaa Blast® is your trusted partner for performance, reliability, and long-term value.

Ersaa Blast® – Engineered for performance, trusted for results.

The Sandblasting Process

Initial Assessment

The sandblasting process starts with an assessment of the project. This step involves examining the surfaces to be treated, selecting the appropriate abrasives, and discussing client needs.

Surface Preparation

Next, the area undergoes preparation for sandblasting. This includes cleaning the site and protecting any sensitive materials from the abrasive materials.

Execution of Sandblasting

During the actual sandblasting process, a sandblasting machine propels the chosen abrasive at high speeds onto the designated surfaces. The operator carefully controls pressure and angle to ensure the desired effects without damaging the underlying material.

Final Inspection

Once sandblasting is complete, a final inspection occurs to confirm that the surfaces meet the necessary standards. Any additional touch-ups can be performed at this stage to guarantee quality.

Maximizing Your Sandblasting Efforts

Sandblasting services in Oman play an essential role in multiple industries, providing crucial surface preparation and restoration solutions. By understanding the available materials, the benefits of sandblasting, and how to choose the right provider, businesses can make informed decisions that significantly enhance their operations.

If you aim to maintain equipment, restore surfaces, or prepare for painting, investing in professional sandblasting services can lead to substantial improvements in overall quality and efficiency. With the right knowledge, companies in Oman can effectively utilize sandblasting to achieve remarkable outcomes.

By following this guide, you will confidently navigate the world of sandblasting in Oman, ensuring that your projects are completed to the highest standards.

Tags:

Sandblasting Services Oman

Surface Preparation Muscat

Industrial Sandblasting Sohar

Grit Blasting Duqm

Abrasive Blasting Salalah

Garnet Blasting Oman

Copperslag Blasting Muscat

Aluminum Oxide Blasting Sohar

Sandblasting Contractors Duqm

Sandblasting Equipment Oman

Blasting Accessories Oman

Blasting Machines Muscat

Airless Painting Machines Oman

Electrical Painting Machines Sohar

Industrial Coating & Blasting Salalah

Surface Protection Oman

Corrosion Removal Muscat

Asset Maintenance Sohar

Industrial Services Oman

Comments